Aluminum Anodizing Machine

Aluminum anodizing machine:

1, Manual/semi automatic/full automatic

2,PP tanks/PVC/FRP

3,Indirect chiller/direct chiller

Aluminum anodizing machine is used for making anodizing surface effect and do color on aluminum profile, when choose aluminum anodizing machine, the following items will affect the quotation:

1, Tank types:PP tanks,Concrete tanks with PVC,Concrete tanks with FRP

2, Tank length,width and height

3, Tanks quantity

4,Chiller capacity, chiller type, direct chiller or indirect chiller , and chiller quantity

5,Rectifier types, quantity,capacity

6,Dye color or rectifier coloring type

7,control system, manual loading/unloading,automatic loading/unloading

8,have air stirring system or not

9,circulation pump capacity

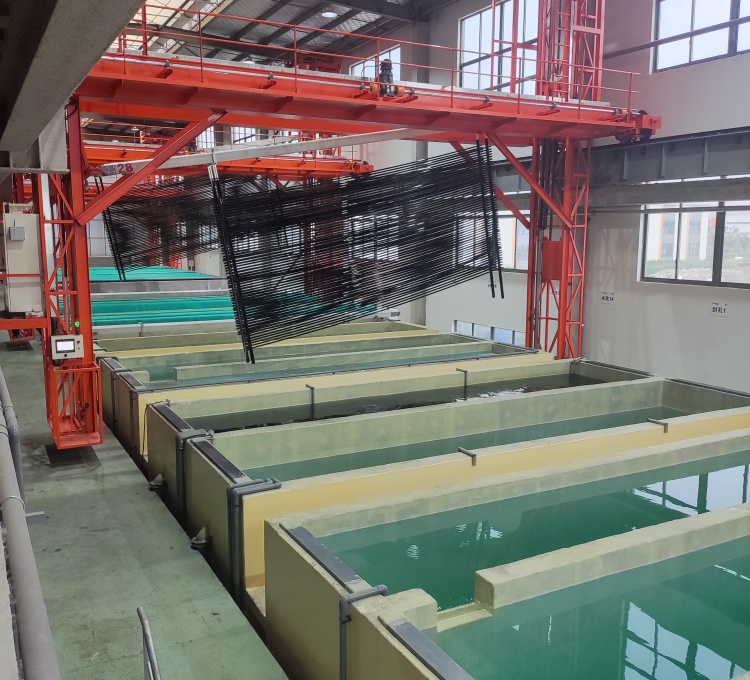

Jordan automatic aluminum anodizing machine use PP tanks, SS 304 tanks for sealing and hot water, MS steel tanks for etching tank.

Jordan anodizing line is under installation, share some photoes:

The function of aluminum oxidation equipment is to use electrochemical methods to form a tough artificial oxide film on the surface of aluminum. The main purpose is to improve the corrosion resistance, wear resistance, hardness and decorative properties of aluminum, making it more durable and beautiful. It is suitable for electronics, automobiles, construction and other industries. It can also be dyed and textured to achieve surface treatment that balances functionality and aesthetics.

Core functions

Enhanced corrosion resistance: The artificial oxide film is thicker and more stable than the oxide film naturally formed on the surface of aluminum materials, and can effectively prevent corrosion of aluminum materials in humid, marine or industrial environments.

Improve hardness and wear resistance: The hardness of the oxide film is much higher than that of the aluminum itself, which can significantly enhance the wear resistance of the aluminum and is suitable for parts that are subject to frequent friction or impact.

Beautification and decoration: The oxide film has a porous structure and is easy to absorb dyes. It can achieve various colors and effects (such as matte, bright), and improve product aesthetics and brand image.

Excellent insulation: The oxide film is an insulator and can be used in electronic product casings and other occasions that require electrical insulation.

Enhance adhesion: Provide a good base for subsequent coatings, inks or adhesives to improve adhesion performance.

Main application areas:

Electronic products: mobile phones, laptop cases, heat sinks, etc., providing protection and beauty.

Automotive industry: wheels, engine parts, etc., resist corrosion and wear.

Construction and decoration: doors, windows, curtain walls, railings, etc., providing long-lasting weather resistance.

Military industry and medical industry: weapon parts and surgical instruments require high durability and biocompatibility.

Consumer products: cameras, watches, kitchen utensils, etc. to improve texture and durability.

Device implementation:

Anodizing equipment controls the growth process of the oxide film through electrolyte (such as sulfuric acid, chromic acid, etc.) and current, and can realize films with different properties and appearances such as ordinary film, hard film, porcelain film, bright film, etc., and combines with sealing treatment to improve the final performance.