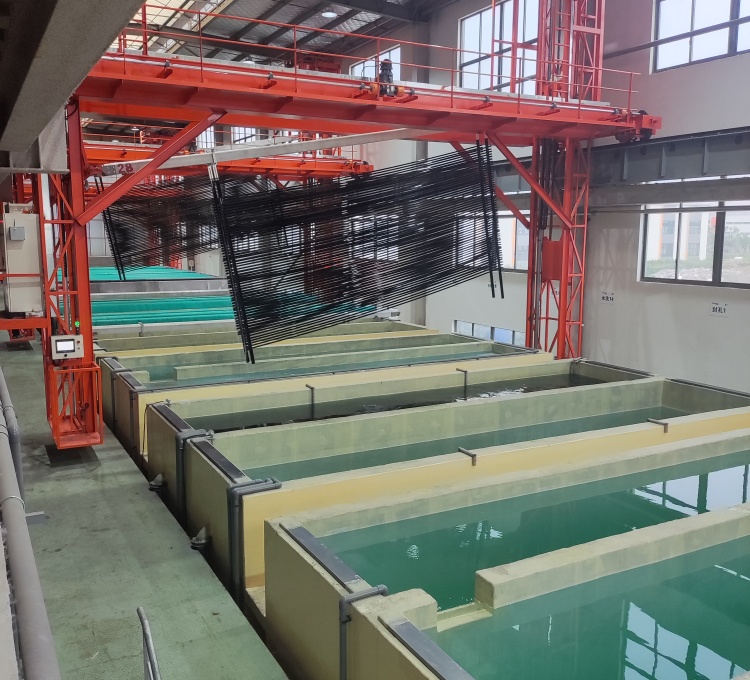

Aluminum Anodizing Metal Electroplating Plant

Aluminum anodizing plant:

1,aluminum surface treatment

2.aluminum coloring treatment

3,aluminum dye color treatment

When we design aluminum anodizing plant, we focus on:

1,save space, the tanks can be put on floor or under floor,sevel layers of building

2,customized design on basis of customer's condition

3,supply capacity is little bigger than customer current requirement, prepare for future bigger production purpose

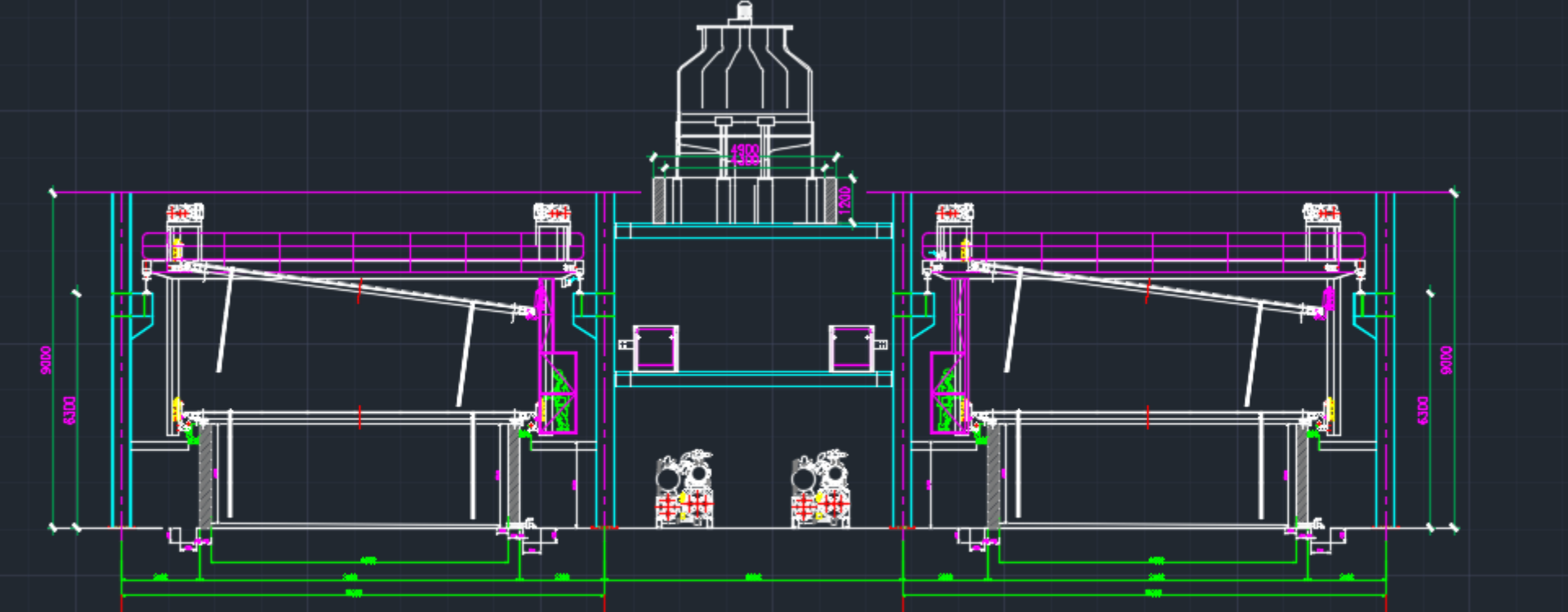

On this design, the tanks on the floor, second floor to put rectifier, electrical cabinet etc

under second floor, put natural gas heater,chiller,pumps etc

the third floor put cooling tower, suction smell device

many customer do not like to put cooling tower on third floor, so we will put outside of workshop,supply customized design for aluminum anodizing plant

Different metal electroplating plant process flow are different,most metal anodizing plant we do is for aluminum electroplating plant.

For aluminum electroplating plant, different surface requirement, aluminum anodizing plant design process are different:

1,if need shining effect, before degreasing,need mechanical polishing and chemical polishing

2,if need sand blasting effect, before anodizing, need sand blasting machine or Etching sand effect

3,if need hair line effect, before anodizing, do hair line effect first

The next process of aluminum anodizing plant :

Degreasing

water rinse

Etching

water rinse

Neutralize

water rinse

Anodizing

water rinse

Coloring/dye color

water rinse

sealing

water rinse

Need customized design of aluminum anodizing plant, contact us:

Ms Melody Li

Whats app/wechat/mobile:+86 13450531604

Email:melody@chanjeou.com