Raw Material PA66 GF25 for Extrusion Polyamide Thermal Break Strips

Polyamide strips, commonly used as thermal breaks in aluminum window and door frames, are primarily made from raw material polyamide 66 (PA66) reinforced with glass fiber (GF). These strips are designed to minimize heat transfer, improving the energy efficiency of buildings.

Raw material Polyamide 66 (PA66):high performance polyamide known for its strength,toughness,and resistance to high temperatures.

Raw material Glass Fiber Reinforcement (GF):

Glass fiber is added to PA66 to enhance its mechanical properties, including tensile strength, flexural modulus, and impact resistance. It also helps to reduce the shrinkage rate of the material during processing.

Various additives may be included to improve specific properties, such as flame retardants for enhanced fire resistance for raw material thermal break strips

Extrusion Grade:

The material is typically in the form of granules (or pellets) and is designed for extrusion, a process used to create the long, continuous strips.

Key properties of polyamide thermal break strips:

· High mechanical strength and toughness: Enables the strip to withstand stress and strain during installation and in use.

· Excellent thermal insulation: Reduces heat transfer, keeping interiors comfortable and reducing energy consumption.

· Corrosion and weather resistance: Ensures durability and longevity in various environmental conditions.

· Good dimensional stability: Minimizes dimensional changes due to temperature fluctuations or humidity.

· Easy processing and assembly: Can be readily extruded into various shapes and sizes, and easily integrated into window and door profiles.

Polyamide thermal break strips are typically made from PA66GF25, a composite material of polyamide 66 and glass fiber, designed for use in window and door frames to improve thermal performance and energy efficiency.

Raw material PA66 GF25 send to Uzbekistan

Monthly production capacity for Raw material thermal break strips: 1000Tons

Quality level for Raw material PA66 GF25:High level

Delivery time for Raw material PA66 GF25:10days for one container

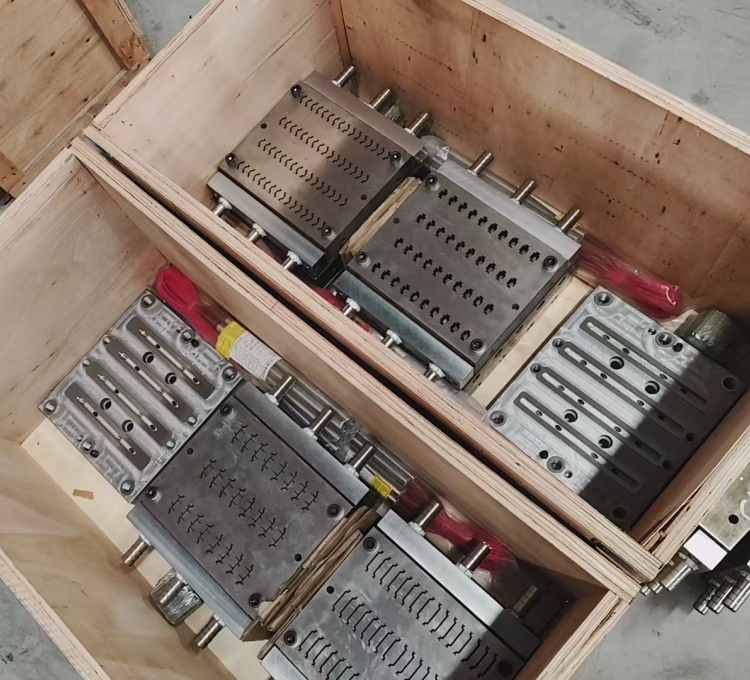

With raw material Thermal break strips, also send Thermal break strips mould

Advantage:

One stop solution for thermal break strips , raw material polyamide, thermal break strips mould, and strips extrusion machine

Complicated moulds are available

Fast delivery

High precision process machine for thermal break strips

Long term experience for manufacture

Polyamide strip extrusion machine dispatch together with Raw material polyamide, polyamide extrusion moulds

Contact us for Raw material PA66 GF25, good price, high quality, one stop solution for thermal break project.